The wheel bearing is a high volume SKU with disproportionate business risk in the international automotive aftermarket. The decisions you make about sourcing in this case directly determine the profitability, warranty exposure and the long-term brand integrity of importers, wholesalers and distributors. Failure in the field is more than just a partial return, it is a customer complaint, an expensive comeback, and a stain on your reputation.

This guide presents the actual factory experience of DUHUI Bearing as a professional wheel bearing producer instead of the basic catalog data. We look at the car wheel bearing as a safety critical precision part, not just an ordinary part. We want to give you, as a professional buyer, real production data that can enable you to see quality bearings not only based on price and packaging but also to ensure that what you buy is safe in use and will not damage your business.

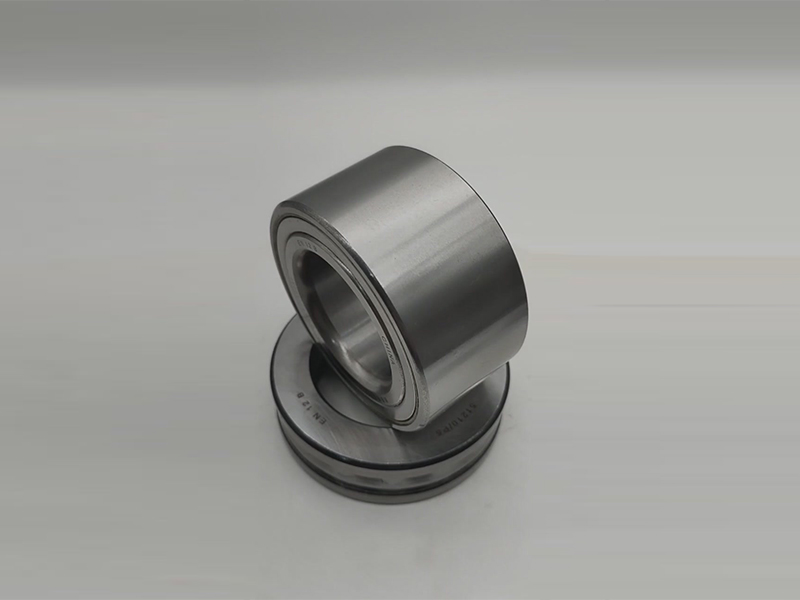

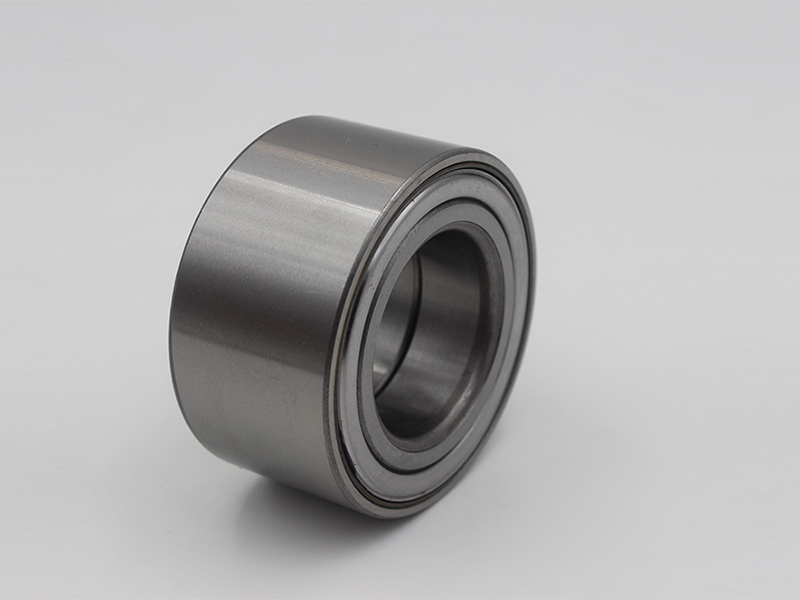

1. Components of Wheel Bearings

A wheel bearing is a complete system in which all its components work together. The breakdown of any parts results in the failure of the entire assembly.

1.1 Inner Ring

As the component press-fits onto the rotating axle or shaft, its bore tolerance (typically h6) and raceway profile are paramount. We monitor for circularity error and taper using high-precision roundness testers. Its carburized case must have a controlled depth (e.g., 0.8-1.2mm) and a smooth hardness gradient to the core. This prevents “case crushing” under extreme shock loads while resisting surface-initiated spalling fatigue.

1.2 Outer Ring

Housed in the steering knuckle, its outside diameter (typically k6) ensures a proper interference fit for stability. A critical failure mode is thermal distortion (ovalization) during the quenching phase of heat treatment. DUHUI technical experts successfully reduced the problem by repeated quenching and tempering tests. This guarantees the ring does not distort the bearing’s internal geometry when pressed into its housing, which would destroy the engineered clearance.

1.3 Rolling Elements (Balls or Rollers)

The rolling elements endure maximum levels of Hertzian contact stress. The Grade 10 (G10) precision or higher is required according to ISO 3290. The size variation in a set is controlled to fractions of a micron level. Optical comparators and surface roughness analyzers are applied to test the roundness and profile of the balls and rollers respectively. This avoids the situation of “weakest link” attributed to a single large constituent carrying a large share of the load, which contributes to early fatigue of the whole bearing.

1.4 Bearing Cage (Retainer)

The cage is more than just a keeper of components, it maintains space between elements at high speeds with low drag and low wear. The choice of material is smart:

- Stamped Steel Cages – These are strong and cheap for many uses.

- Polyamide Cages (e.g., PA66-GF25) – They are excellent at resisting rust, are self-lubricating, and are quieter – perfect for the modern, near-silent passenger cars.

The layout of the cage has the pockets and windows in all the right places to ensure that the grease flows to where it should and also to minimise grease being spun away due to high speed.

1.5 Bearing Seals

We design seals as complete, multi-component assemblies. A high-performance seal typically incorporates: a primary sealing lip (from NBR or FKM compound), often an auxiliary dust lip, a stainless steel garter spring to maintain consistent interfacial pressure, and a robust, often phosphate-coated steel outer casing engineered for secure press-fit retention. The geometry and interference of the lip are optimized against the hardness and finish of the counterface to ensure effective sealing with minimal friction.

1.6 Lubricating Grease

The selection of the grease is a process, in this case. We conduct thorough bench tests, which include focus point, oil separation, strength, and corrosion protection (Emcor test). In the case of hub units, the long-term performance is simulated using the DIN 51821 (FE8) bearing wear tests. The grease is not a mere filling but is packed in a controlled manner such that all the critical surfaces, raceways, rolling elements and cage are fully coated before the first rotation hence avoiding dry-start wear.

2. Types of Wheel Bearings

2.1 Ball Bearings

Predominant in passenger cars due to low starting torque and excellent high-speed capability.

Sourcing Insight for Buyers: Their point contact design is highly sensitive to alignment, finish, and contamination. Inconsistent manufacturing quality manifests almost immediately as unacceptable rumble or whine (NVH issues). When sourcing ball bearings, prioritize manufacturers who can provide Statistical Process Control (SPC) data for raceway finish (Ra) and, crucially, NVH test reports from finished bearing audits.

2.2 Roller Bearings

The design choice for applications with significant radial and axial loads: SUVs, light trucks, and commercial vehicles.

Sourcing Insight for Buyers: The line contact design offers higher load capacity but demands exceptional precision in geometry and heat treatment. Subpar material or processing leads to edge loading and rapid spalling. When sourcing tapered roller bearings, insist on reviewing the supplier’s Material Test Certificates (MTC) and heat treatment batch records. The conicity and profile matching between the rollers and raceways are critical for performance and must be impeccably controlled.

2.3 Single Row Bearings

The single row bearings are composed of one series of rolling elements, which are arranged between the inner and outer rings. This is a simple type pattern design which is common in vehicles, especially in the normal design of wheel bearings as well as numerous first generation hub units.

- Simple Design: It is easy to produce hence may be cheap in mass production.

- Radial Load Focus: The major ones are created to hold radial loads although many angular contact single row designs can hold big axial loads in a single direction. Adjustable or

- Pre-Set Clearance: In tapered roller bearing configurations, the internal clearance (preload) can be finely adjusted during installation, allowing for precise setting. In modern single row ball bearing hub units, this clearance is factory pre-set and sealed

Single row designs are prevalent in many passenger vehicles, especially older models or simpler axle designs. They represent a mature, cost-optimized engineering solution where load conditions are well-understood and predictable.

2.4 Double Row Bearings

Double-row bearings also have two separate rows of rolling elements rolled within a single, compact package. This is a modern design used in the hub bearing units (WHBs) of passenger vehicles as well as SUVs since the design is more integrated and high-performing.

- Compact, Integrated form: Two bearing rows are used on a common outer ring (and occasionally inner ring), which is a more rigid and space-saving solution compared to two separate bearings installed in parallel.

- Enhanced Load Capacity & Stability: The two-row arrangement provides naturally more load strength in the direction of the axis and against moment force. This provides better accuracy in vehicle control and longer life.

- Factory-Optimized Preload: The internal preload or clearance between the two rows is meticulously set and sealed at the factory. This eliminates installation adjustment, ensures optimal performance, and is critical for achieving low noise (NVH) levels.

Double row bearings are the dominant design in Generation 2 and Generation 3 hub bearing units. They are the engineering response to demands for greater load capacity (from heavier vehicles, larger wheels), improved handling, and integrated functionality (ABS sensors).

Sourcing Consideration: This design represents the current industry standard for most new passenger vehicle platforms. For you as a buyer, it translates to a product that is:

- Less Prone to Installation Error: Being a pre-set, sealed unit.

- Often More Profitable: As a higher-value, integrated assembly.

- Future-Oriented: Aligning with automotive design trends.

When you are purchasing double row bearings or hub bearings, you need to ensure that the manufacturer is able to properly fit and sustain the preload and the position of the two rows of bearings. The noise will be greater or they will be shorter when their quality is different. Select a hub bearing manufacturer like DUHUI, which has state of the art technology in assembly and testing to ensure that this vital double row bearing system is perfect.

3. Functions of Wheel Bearings

A good wheel bearing is a point of rotation that performs more than one task. Its required functions at the same time have an impact on the safety of the vehicle, its performance and the consumers’ impression of the brands you deliver.

3.1 Supports Multiple, Multi-Axial Loads

It serves as the main structural load-transfer channel between the wheel and the vehicle, and it is used to handle a composite stress state.

Radial Load: The static and moving weight of the car. Axial (Thrust) Load: The forces that are produced during turning (side to side) and braking/acceleration (front to back). Moment Loads: Bending forces due to hitting potholes or curbs.

A good bearing spreads these complicated loads evenly on all the rolling parts. A bad one having uneven hardness of material or inaccurate shape has local stress. This causes accelerated fatigue spalling, which in turn causes audible play and noise, which are sure signs of warranty issues and customer complaints.

3.2 Allows Accurate, Easy Rotation

Apart from enabling movement, a high quality bearing reduces rolling resistance by the combination of perfect shape, excellent finish and best grease. The physical advantages are: Lower Drivetrain Friction: Assists in the fuel efficiency of vehicles. Silent, Vibration-Free Running: Provides better ride quality.

Bad manufacturing creates extra friction. This makes the grease get too hot and break down. The metal also changes. A fast failure cycle then begins. Customers normally experience an initial light buzz or variation in the driving sense of the car before more serious and expensive problems occur.

3.3 Maintains Accurate Wheel Alignment and Runout

The bearing is the geometric fiducial point for the whole wheel assembly. It should have almost zero lateral and radial runout (normally less than 0.05 mm) to ensure that:

- True Brake Rotor Runout: It eliminates brake judder and pulsation in the steering.

- Even Tire Contact Patch : Even Tire Contact Patch is used to eliminate irregular wear patterns between cupping and feathering.

Such accuracy cannot be upheld by a bearing that bends under load or has too much internal clearance. This results in not only a defective bearing but also secondary damage to high-priced tires and brakes, which complicates the repair, makes it more costly, and frustrates customers to a higher level.

3.4 Serves as the Foundation for Ancillary Safety Systems

The modern wheel bearings are part of the electrical systems that make vehicles active.

The wheel bearings provide a stable surface which allows the brake rotor to move in the braking system. The clearance in the bearings will influence the performance and response of the braking system.

The WHBs of Generation 3+ contain an integrated magnetized encoder ring that is enclosed with an objective wheel speed signal. This signal is employed in three systems which are the anti block braking system (ABS), traction control system and the electronic stability program system.

4. Principle of wheel Bearings

The theory of low friction rolling instead of high friction sliding is easy to understand. Achieving this principle under harsh circumstances over more than 150,000 miles of reliable operation is a huge engineering challenge. Production processes are the ways in which theoretical concepts are transformed into actual long-term performance.

4.1 The Friction Change Process in Practical Operation

Complete rolling contact should be maintained to provide high service. The load that is applied should be distributed between the inner ring and the outer ring and through all rolling elements. Geometric mistakes lead to microscopic slip and scrubbing. These are not short-term slides, leading to high temperatures and wear. The main production aim is to eliminate this negative micro-slip during the life cycle of the bearing.

4.2 Achieving Geometric Consistency and Surface Integrity

Smooth, quiet operation is a direct function of micro-perfection. After heat treatment and initial machining, we employ a sequenced process: hard turning, precision profile grinding, and finally superfinishing. Superfinishing, often using fine abrasive films or tapes, polishes away the microscopic “peaks” left by grinding. This creates plateau-like surfaces that dramatically improve lubrication retention, minimize initial wear-in, and are the primary defense against operational noise (NVH). A noisy bearing is frequently the audible signature of poor surface finish.

4.3 Maintaining a Sealed, Contaminant-Free Micro-Climate

The bearing’s working principle is entirely contingent upon a pristine, lubricated interior. The seal system is a tailored defense mechanism. For standard passenger vehicles, a dual-lipped contact seal with a stainless steel garter spring provides robust, balanced protection. For off-road or extreme environments, we may specify a labyrinth seal combined with an integrated flinger, creating a tortuous path that deflects contaminants centrifugally. The seal material itself is compounded to resist hardening, cracking, and chemical degradation from road salts, ozone, and temperature swings.

4.4 Understanding Engineered Internal Clearance

Internal clearance is a pre-load compensation measure, not a production mistake. We choose a clearance set, for example, C3 in most wheel applications, based on the thermal behaviour and fit of the particular vehicle. The math ensures that once you add in fit reduction (by pressing) and heating in service, the residual clearance under load will be just right to give good performance and long life. If the factory clearance is wrong, then it will always become evident soon after installation as a sound and play (when too loose) or instantaneous heat-induced failure (when too tight).

5. Basic Definition of Wheel Bearings in the Aftermarket

In technical automobile lingo, a wheel bearing is a sealed, high-precision mechanical component that performs two basic tasks at once-supporting load and rotation. To support load It is used to bear the weight of a vehicle, i.e., a radial load. It also controls forces which occur when turning and braking (axial loads). To rotate it allows the wheel to spin with little resistance around a still axis or a steering knuckle.

Its multiple structural and motion functions make it a safety-essential component. It influences vehicle control and stopping power and fuel usage and total safety.

This is the definition that business buyers should begin with. The next check of a bearing’s quality-whether it simply fits or works properly-depends on how well it was made.

6. Technical Points of Wheel Bearing Manufacturing

The five production points of wheel bearings determine their performance in practical applications. These manufacturing points determine the production expertise of different manufacturers since they create field performance disparities between manufacturers.

6.1 Bearing Steel & Heat Treatment

Material selection is the primary factor that determines the durability of bearings. To create strong bearings, manufacturers utilize high-carbon chromium steel (SAE 52100/GCr15) that undergoes vacuum-degassing to achieve a uniform and pure microstructure. Through case carburizing heat treatment, bearings acquire a hard surface that resists wear (58-64 HRC) while maintaining a strong core that absorbs impact forces. The raceway surface will flake due to poor heat treatment which causes premature spalling as a primary failure mode.

6.2 The raGeometry and Surface Finish of Raceway

The rolling element tracks, also referred to as raceways, are essentially precision (smooth and even) tracks that a rolling element follows. The performance of raceways is determined by the geometry (shape, size and position) and surface finish (roughness).

It is the final finish of raceways that ultimately influences a bearing on the rolling-element noise against what is heard when a bearing operates quietly relative to what is heard that generates complaints of noise as audible feedback. Rolling Element Noise is defined as the sound complaints generated during operation, against the sound of the machine being silent either based on the absence of sound or reduced level of sound performance.

6.3 Internal Clearance Control

The internal clearance (C2, C3, etc.) is not a manufacturing tolerance error. It is a previously measured gap that is created to accommodate thermal expansion and the compression of press-fit installation. The correctly adjusted clearance provides the best load distribution in service. Incorrect clearance leads to rapid failure, insufficient clearance results in overheating, and excessive clearance generates noise and wheel play.

6.4 The Design and Materials of Seal Ring

A bearing’s interior must remain a pristine, grease-filled environment. The seal is its primary defense. Effective sealing requires a multi-faceted approach: the right design (e.g., contact vs. labyrinth seals), durable lip materials (NBR, FKM) suited to the environment, and secure integration into the bearing ring. Since contamination ingress causes the vast majority of premature failures, the seal is the most critical component for achieving design life.

6.5 Grease Formulation & Application

Wheel bearing grease is a high-performance compound, not a simple lubricant. It is a balanced system of base oil (for viscosity), thickener (e.g., lithium complex, polyurea), and an additive package (anti-wear, anti-corrosion). The grease must be matched to the application’s speed and temperature range, and applied in a precise quantity and method to ensure all surfaces are protected from the first rotation to the end of service life.

7. Installation Location of Wheel Bearings & Market Planning

Wheel bearings are installed between the hub and the knuckle of the steering system or axle, permitting the wheel to rotate smoothly. This stress at this installation point determines the performance of the bearing and influences your business strategy and support requirements.

7.1 Installation and Market

Product structure is influenced by the location of wheel bearing, and the market approach is determined by it. The installation of the standard component (press-fit) bearings requires the use of special hydraulic presses, mandrels and trained personnel, and after the installation, the bearings have to be adjusted. The new Wheel Hub Bearings (WHBs) are simple bolt-on assemblies which are pre-assembled, pre-adjusted and pre-sealed cartridge units.

7.2 Common Bearing Faults

The pivotal aspect of a bearing is that it is a crucial attachment point between other parts of a car. In the event of malfunctioning bearings, it may result in the following system faults:

- Brake Disc Thickness Variation- DTV: The excessive amount of time that the bearing spends out-of-round will affect the functioning of the brake disc, resulting in vibration of the brake, and pulse of the steering wheel.

- ABS/ESP Faults: Gen 2+ WHBs have a hard magnetic encoder ring. It gives incorrect signals of wheel speed when broken or out of place, which turns on the dashboard lights and turns off the systems such as ABS or ESP.

Installers often misdiagnose these faults. This diagnostic error generates redundant warranty requests. The dissatisfied customers request multiple service installers for repeated work. The correct diagnostic solutions prevent expenses of repeat service visits.

7.3 Packaging and Shipping

The significant forces it withstands in service inform our packaging philosophy. We engineer packaging with rigid, form-fitting internal supports to prevent transport brinelling—the permanent indentation of raceways caused by vibration or impact during shipping and handling. This proactive, often overlooked detail prevents Dead-On-Arrival (DOA) claims, preserves the product’s engineered performance, and protects your profit margin from freight and replacement losses.

8. Choose DUHUI – Your Reliable Wheel Bearing Supplier

Choosing a rirht wheel bearing supplier is one of the most important decisions for your. The true cost is not the unit price, but the Total Cost of Ownership (TCO): purchase price + warranty administration + logistics of returns + cost of lost customer trust + brand equity erosion.

DUHUI Bearing operates as a technical manufacturing partner, not just a supplier. We control the critical path from alloy selection to sealed, tested unit, embedding quality at every stage through process discipline and application-specific engineering. Our focus is on delivering consistent, validated performance that becomes a reliable, profitable cornerstone of your automotive parts portfolio.

Your reputation is built on the quality you deliver. Partner with a manufacturer engineered to protect it. Contact DUHUI Bearing today to initiate a technical and commercial discussion about how our reliable wheel bearing solutions can secure your supply chain, reduce your risk, and strengthen your position in the market.

9. FAQ Guide for Wheel Bearings

9.1 Wheel Bearing vs. Wheel Hub Bearing

It is important to distinguish between traditional wheel bearings and modern wheel hub bearings (WHBs). This is a fundamental difference in product design and integration, not merely terminology.

1 Definition & Design

Wheel bearings refer to anti-friction mechanical parts that are made up of an inner ring, outer ring, rolling elements (balls or rollers), and a cage. This can be bought separately. In vehicles, it is pressed to the wheel hub and steering knuckle as separate parts and requires other components such as an axle nut, seal and usually an external ABS sensor.

Wheel hub bearings (Hub Assembly) are a combination part that is a combination of parts. The bearing and a wheel hub are included by default. Modern Gen 3s also contain the ABS speed sensor ring. It is a ready cartridge.

2 Main Differences

| Wheel Bearing (Component) | Wheel Hub Bearing (Unit) | |

| Components | A component (ball set, roller set, cups/cones). | A complete, sealed assembly (bearing + hub ± sensor). |

| Installation | Press-fit. Requires a hydraulic press, specific mandrels, and technical skill to achieve correct fit and clearance. High precision during installation. Risk of damage from improper pressing or adjustment. | Bolt-on. Mounts directly to the steering knuckle with bolts. The critical internal preload is set at the factory. Correct procedure and torque specification are critical. Less dependent on installer’s bearing-specific expertise. |

| Applications | Traditional design, common in older vehicles and some heavy-duty/industrial applications. | The dominant design in modern passenger vehicles (post-~2000). Represents an engineering shift towards higher integration, reliability, and assembly efficiency. |

3 Manufacturer’s Perspective: Why the Distinction Matters

The shift from component bearings to integrated hub units is a clear industry trend driven by vehicle design. For a wheel bearing manufacturer like DUHUI, producing a hub unit demands broader engineering capability: it requires mastery of the core bearing technology plus precision machining of the hub, robust sealing, and often the integration of sensor electronics.

9.2 What is the importance of Wheel Bearing for inventory?

A wheel bearing is a component set (inner/outer rings, rolling elements) requiring professional press-fitting, adjustment, and often separate sealing. A Wheel Hub Bearing (WHB) is a pre-assembled, pre-adjusted, pre-sealed “cartridge” that bolts directly into the steering knuckle.

The aftermarket trend decisively favors WHBs (especially Gen 3 with integrated ABS) because they eliminate the #1 cause of premature failure: installation error. This translates directly into fewer warranty claims, fewer comebacks, and higher installer satisfaction for your customers.

9.3 What are the typical symptoms of a bad wheel bearing?

If your client informs you that his wheel bearing is broken, kindly ask him to provide the actual symptoms. The wheel bearing is malfunctioning in case the symptoms are the same as the ones indicated below.

- It is a deep persistent growl or hum.

- The sound varies when the vehicle is turning as weight shifts.

- A vibration may be felt on the steering wheel, floor or seat.

- The wheel is loose and the tire is wearing abnormally.

9.4 What are the root causes of wheel bearing damage ?

As a bearing producer, we have found that the wheel bearing failures occur due to improper installation or accidents, and other technical malfunctions which occur due to:

- Seal Failure – this is the major cause- it allows sand, aluminum oxide and water to get in corroding and scraping the bearing.

- Lubrication Failure – this is caused by grease cooking (high heat), thinning, washing out or simple instances of not enough grease.

- Material/Heat Treatment Defect: Subsurface inclusions, improper case depth or hardness, or grinding burns creating residual tensile stress.

- Geometric Stress Raisers: Imperfect raceway profiles or rolling elements causing edge loading or stress concentrations.

9.5 What is the actual service life of a quality wheel bearing?

Under normal operating conditions (correct installation, proper alignment, no severe impacts), a premium-grade wheel bearing should reliably achieve 150,000 to 250,000 kilometers.

Service life is a function of the L10 life calculation, which is heavily influenced by the applied load. Consistent failure well before 100,000 km is a strong indicator of fundamental quality issues or a severe application mismatch.

9.6 How do I check returned wheel bearings for basic faults as a seller?

When your customer reports that their wheel bearing has failed and wants to return it, you need to check the problem to save money. Here are some easy but effective ways to do it:

- Visual check: Check for rust behind the seal (shows that water got in), blue/brown discoloration on the raceway (shows that the part was overheated), or visible pitting/flaking (shows that the part is fatigued and worn out).

- Manual check: Move the part manually and feel for gritty, binding, or rough movement. These show the presence of contaminants or damage to the surface.

- Clearance check: The clearance, both axial and radial, should be measured using a dial indicator. Severe wear or clearance failure is shown by excessive clearance (normally greater than 0.05 mm).

9.7 As a seller, how do I perform basic fault checks on returned wheel bearings?

When your customer reports wheel bearing failure and requests a return, you should perform basic troubleshooting to avoid unnecessary financial loss. The following are the basic things that you may do:

- Visual inspection: Inspect the rust behind the seal (indicating subsurface water), blue/brown on the raceway (indicating overheating), or apparent pitting/flaking (indicating fatigue damage).

- The manual rotation: Rough, binding, or rough. This is an indication of foreign materials or surface damage.

- Clearance check: a dial indicator is used to check the axial and radial clearance. High clearance, normally at 0.05 mm, shows heavy wear or clearance failure.

9.8 What are the precautions for wheel bearings Installation?

It is the installation of wheel bearings that determines how they perform and serve your installers or end users. When not installed correctly, the product will be lost prematurely and warranty claims will ensue. Communicate to distributors and customers this information to save your good name and eliminate unneeded service problems afterward.

Main Point: Install correctly with correct tools and be gentle.

1. In Press-Fit Bearings:

- Install tools: Always use a right mandrel tool to make sure that force is applied to the bearing ring that needs a press fit (e.g., when pressing an inner ring, the force is applied only to the inner ring; when pressing an outer ring, the force is applied only to the outer ring). Do not apply pressure through rolling elements as it will result in instant damage to raceways.

- Complete Support: When installing the opposite ring, make sure that the support is flat and even along the entire end surface of the ring. The ring will be distorted in case of an uneven support and this will damage the internal clearance.

- Steady Pressure: Install the bearing slowly and evenly using a hydraulic press. Never hit a portion of the bearing with a hammer.

2. Wheel Hub Bearing Units

- Adhere to torque + angle values: When mounting the Drive-Side Wheel Hub Bearing (WHB), Torque the Hub Nut according to the specified two-step, Torque + angle process of the OEM. It is only through this that the correct internal preload in the bearing can be established. Doing it by just feeling or with a regular torque wrench will not suffice.

- Use New Nuts: The old nuts should never be reused, deformed, or anti-seize riveted hub nuts. New Nuts: Normally have pre-installed adhesive to ensure a uniform locking force.

- Clean the areas: Before installing the WHB to the steering knuckle, make sure that both contact areas are absolutely clean, free of rust and burrs. Tiny grains can result in jamming or irregular play after fitting.

3. The things to note in general:

- Have Proper Cleanliness: The bearings should be in their original package until you install them. Do not allow dust or foreign matter into the sealing system before mounting.

- Proper Storage: Uninstalled bearings should be stored horizontally. Do not pile them vertically since it could cause the bearing rings to deform.

- Post-Installation Inspection: Once installed, spin the wheel by hand before lowering the vehicle to make sure it rotates smoothly without unusual noise or resistance.

You minimize your warranty cost and complaint resolution work, and your technical image and reputation as a professional wheel bearing supplier are enhanced and you are seen as a clear, professional installation guide to your customers, which results in fewer early failures through improper installation..