If you want to know the difference between a wheel bearing and a wheel hub bearing? If you want to know if your car’s wheel bearing is damaged? If you want to know when your car’s wheel bearing should be replaced, as a bearing company with 20 years of experience, DUHUI will explain to you what a wheel hub assembly and wheel hub bearing are, and how to determine which part in your vehicle is faulty.

1. What is a Wheel Bearing & Hub Bearing ?

A wheel bearing is a fundamental mechanical component: a set of precision steel balls or rollers held within inner and outer races, designed specifically to enable smooth, low-friction rotation of the wheel hub.

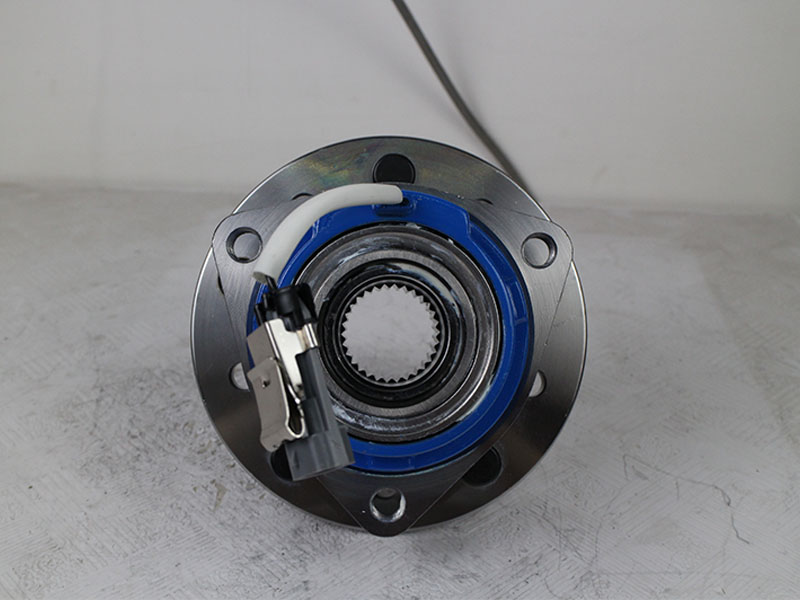

In contrast, a wheel hub assembly (often called a hub bearing unit) represents an evolution in design. It is a pre-assembled, sealed module that integrates multiple parts into one complete unit. At its heart is a wheel bearing, but it is permanently housed within a casing that also includes the wheel hub flange (where your wheel bolts on) and, critically, an integrated ABS sensor ring.

2. The Main Differences Between Wheel Bearings and Hub Assemblies

Despite the two bearings having the same primary functions, they are significantly different in other aspects. The differences are divided into five sections that are Components, cost, performance, installation, and maintenance.

2.1 Composition & Design

The traditional wheel bearing is a separate component. It is element of a larger whole, and it should be installed separately in the wheel center of the vehicle and the carriage of the steering system. It is in separate contact with the axle and seal and also an ABS sensor installed outside in most cases when in operation.

On the contrary, a modern wheel hub unit is a single complete unit that is designed by DUHUI and other manufacturers the bearing is pre-installed and pre-greased and permanently sealed in a durable housing that contains the mounting flange and sensor characteristics. The integrated design is the standard one in most vehicles, which have been manufactured for the last 15-20 years with the view of reliability and efficiency in assembly.

2.2 Cost Analysis: Part Price vs. Total Job Cost

Most people make the mistake of considering only the price of the part.

Typically, a loose wheel bearing is less expensive by a significant amount. Yet, that is not a deceptive method of considering the entire job expenses. The replacement of an inserted bearing is both time-consuming and laborious. It requires a hydraulic press, special adapters, and a considerable amount of time with a professional mechanic. It all becomes costly very quickly.

Although a wheel hub assembly can be more expensive in terms of the part, it is engineered as a bolt-on solution. The replacement work is very easier and quicker, hence the total cost of repair may be less or equal to that of replacement. This provides you with a clear cost estimate and value when selecting a quality unit, which will be easy to install.

2.3 Performance & Reliability

The pressed-in wheel bearing is highly dependent on the ability of the installer to function well. The desired preload of the bearing must be during the installation since when it is tight, it heats up and fails early and when it is loose it creates harmful play. The instances of this human variable normally result in vast volumes of return visits.

This threat is eliminated by a wheel hub assembly. Hub units are assembled in the controlled factory environment of DUHUI, and the bearing preload is correctly adjusted and sealed for good. Maximum performance, uniform life, and peace of mind right from installation translate into a more stable end-user drive.

2.4 Installation Process & Complexity

This distinction appears most clearly when you are repairing. The replacement of a wheel bearing should be performed in a completely equipped workshop. This involves removing the hub, utilising a powerful press to press the old bearing out of the knuckle and then carefully pressing the new bearing in without damaging it, which requires precise tools and expertise.

Removing a wheel hub assembly is much easier. Having done basic dismantling (wheel, brake caliper, rotor), the old assembly is simply unbolted from the steering knuckle. The new hub assembly of DUHUI is bolted on directly, the ABS sensor is plugged in, and the wheel is reinstalled. This bolt-on characteristic renders it much more accessible to experienced DIY enthusiasts with the right tools.

2.5 Maintenance & Serviceability

In the context of modern automotive repair, both are largely considered “maintenance-free” units. The era of manually repacking greaseable wheel bearings is mostly gone. Both sealed wheel bearings and complete wheel hub assemblies are designed not to be opened or serviced.

When the bearings become useless as a result of wearing, contamination, or fatigue, or when this occurs, the normal procedure is to substitute the bearings entirely. Rather than maintenance, it is better to select a quality bearing that has excellent seals, quality grease, and accurate tolerances at the outset. And this is the advantage of DUHUI’s 20 years of manufacturing experience.

3. Symptoms of a Failing Wheel Bearing / Hub Assembly

Identifying fault signals is important to us. It can prevent more serious damage and unsafe driving conditions.The symptoms often overlap, but key distinctions exist.

3.1 Symptoms of a Failing Wheel Bearing:

The classic sign is an audible cue. You will typically hear a persistent low-pitched humming, rumbling, or growling noise that originates from the wheel area. This noise usually increases proportionally with vehicle speed.

Visually, with the vehicle safely lifted, grabbing the tire at the top and bottom and checking for excessive rocking movement can indicate worn bearing play.

3.2 Symptoms of a Failing Wheel Hub Assembly:

A bad hub assembly will create all the noise and physical symptoms of a bad wheel bearing. But it gets a serious electronic sign on account of its integrated design. The most common extra sign is the ABS (Anti-lock Braking System) or traction or stability control warning light, which appears on your dashboard.

This is due to the fact that the magnetic encoder ring of the wheel speed sensor is integrated in the hub assembly. When the unit fails, is worn out or the sensor itself is built-in and fails, it transmits wrong data to the computer of your vehicle. In very rough cases, you may also experience a strong wheel wobble or vibration, particularly at a high speed.

4. Causes of a Bad Wheel Bearing / Hub Unit

Understanding the common causes of failure helps in prevention and diagnosis.

4.1 Causes of a Bad Wheel Bearing:

The main causes of a wheel bearing wearing out are contamination and installation error.

Although the seals are strong, high pressure vehicle cleaning, deep potholes or driving through deep water can damage seals allowing water, salt and dirt to enter, which will degrade the lubricant and has the effect of abrading the metal. Physical impact caused by road hazards may also damage or bend the bearing races.

Critically, in pressed-in styles, the primary cause of premature failure is incorrect installation using incorrect tools, hammer installation, or lack of correct preload, which emphasizes the need for professional installation or replacement with integrated units.

4.2 Causes of a Bad Wheel Hub Assembly:

The reason for a bad wheel hub assembly is similar : damage by impact and seal failure and normal wear over tens of thousands of miles.

however, prone to other points of failure. A damaged integrated wheel speed sensor or its magnetic tone ring may be caused by debris or corrosion which may cause ABS failures without a typical bearing noise.

In addition, the studs in the hub flange which you attach to your lug nuts can be cross-threaded or broken. Although the bearing might be good, the hub must be replaced as a whole in case the flange is damaged since it is a safety issue.

5. How to Replace a Wheel Bearing / Hub Bearing?

5.1 How to Replace a Wheel Bearing (Pressed-in Style):

- Tool Warning: This requires a hydraulic press, bearing driver/adaptor kit, and significant mechanical skill.

- Safety First: Securely lift and support the vehicle on jack stands. Remove the wheel.

- Gain Access: Remove the brake caliper (hang it safely) and brake rotor. You will likely need to remove the axle nut and separate the hub from the steering knuckle.

- Pressing Out: Mount the hub/knuckle in a hydraulic press. Using the correct-sized adaptors, carefully press the old wheel bearing out from its housing.

- Pressing In: Thoroughly clean the housing. Precisely align the new, high-quality bearing. Using the press and correct adaptors, press it in evenly and squarely until it seats fully. Improper pressing is the #1 installer error.

- Reassembly: Reinstall the hub, new axle nut (torqued to spec), brake components, and wheel. A final check for smooth rotation and no play is essential.

5.2 How to Replace a Wheel Hub Bearing (Bolt-on Style):

This is a more accessible procedure for well-equipped DIYers.

- Preparation: Securely lift the vehicle and remove the wheel. Loosen (but do not fully remove) the large central axle nut while the car is still on the ground for leverage.

- Disassembly: Remove the brake caliper and rotor. Unplug the electrical connector for the ABS sensor.

- Remove the Old Unit: Now fully remove the axle nut. Unbolt the hub assembly from the rear of the steering knuckle (typically 3-4 bolts). You may need a puller or gentle persuasion to free it.

- Install the New Unit: Clean the mating surface on the knuckle. Position your new DUHUI hub assembly, ensuring the ABS sensor port is aligned. Hand-tighten the mounting bolts.

- Final Torque & Reassembly: Reinstall the axle shaft (if removed) and torque the critical axle nut to your vehicle’s exact specification—this is vital. Then torque the hub assembly mounting bolts. Reconnect the ABS sensor, reinstall the brake rotor and caliper, and mount the wheel.

6. Choose DUHUI — Your Trusted Bearing Supplier

The automotive industry is replacing wheel bearings with integrated wheel hub assemblies. This change of trend is due to the fact that drivers need more long-lasting auto parts and good systems of safety and easy servicing. The hub assembly is the best option for most of the new vehicles. It will make sure the vehicle performs at its best.

DUHUI is focused on providing you with a trustworthy and durable wheel bearing. We have been manufacturing wheel bearing since 2003. Every DUHUI product you purchase has been designed to meet the elevated standards that we maintain. We use advanced technology of the seals, quality steel and the exact preload which always results in proper installations. Choose DUHUI to be your wheel bearing supplier.

7. Frequently Asked Questions

7.1 Do I need to replace a pair of wheel bearings?

Yes. First, always replace in pairs (both sides on the same axle). If one fails, the other is under identical stress and likely to fail soon. Second, use a proper torque wrench for all bolts, especially the critical axle nut—improper torque is a major cause of premature failure. Finally, never hammer directly on a bearing or hub assembly; use the correct pullers and tools to avoid damaging the new DUHUI unit you’re installing.

7.2 When To Replace Wheel Bearings And Hub Bearings

Do not ignore these warnings: 1) A persistent growing, humming, or grinding noise from the wheel that changes with speed or turning. 2) Any feeling of vibration or wobble in the steering wheel or vehicle body. 3) An illuminated ABS or traction control warning light on your dashboard (common with hub assemblies). These symptoms indicate active wear or failure that will only worsen, risking safety.

7.3 Is it difficult to replace a wheel hub assembly yourself?

Replacing a bolt-on wheel hub assembly involves basic unbolting and bolting tasks and is considered a viable DIY project for experienced individuals who possess the necessary tools. You need a breaker bar and a torque wrench and jack stands and possibly a hub puller to complete the job.

Replacing a pressed wheel bearing needs a powerful hydraulic press and special adapters which make it a task that should be performed by trained technicians in professional shops.

7.4 Should I replace a wheel bearing or hub assembly?

Your vehicle’s design dictates the part. Always replace with the type of component originally installed. Modern cars overwhelmingly use integrated wheel hub assemblies. For older models designed for pressed bearings, inspect the hub and knuckle for wear; if they are damaged, a complete hub assembly conversion kit (if available) is often a more reliable and cost-effective long-term solution than pressing in a new bearing into a worn housing.

7.5 What happens if you don’t replace a worn wheel hub assembly?

When you never change a bad wheel hub bearing, it will lead to problems. The vehicle will produce more sound and vibrate more. The bearing may become too hot and completely stop working. This may lead to the wheel stopping when driving, which may make you lose control of the car. In the most extreme instances, fractured bearing may result in the wheel totally detaching from the vehicle. It is much more costly to delay than to replace the hub assembly immediately.

7.6 How long does a wheel hub assembly typically last?

In normal driving, a good hub lasts between 85,000 and 150,000 miles. It will not survive long in case you hit the potholes or salt a lot. It is also important how it is made. That is why DUHUI makes them powerful, applies excellent seals and excellent materials so that they will serve you as much as possible.

7.7 Can you drive with a bad wheel hub assembly?

You should drive with extreme caution and only if absolutely necessary to reach a repair shop a short distance away. Drive at low speeds, avoid sharp turns, and do not take the vehicle on highways. Understand that the condition is unpredictable and can deteriorate into a seizure or failure at any moment. It is not safe for normal driving or any extended journey.