Your Professional Tensioner Pulley Manufacturer

DUHUI has specialized in the development and production of automotive tensioner pulleys for 20 years, and “high standards and high quality” is our most important principle. Our tensioner pulley factory is ISO9001 and 16949 certified. The raw materials we use to manufacture the tensioner pulleys and every subsequent process are guided by the GB/T Chinese national standard. We have strict national standards for the materials and performance of the raw materials we select. We also have strict national standards for the specifications of the workpieces we process. And we have strict national standards for subsequent assembly and quality inspection links. High-standards DUHUI tensioner pulleys are currently at the leading level in China.

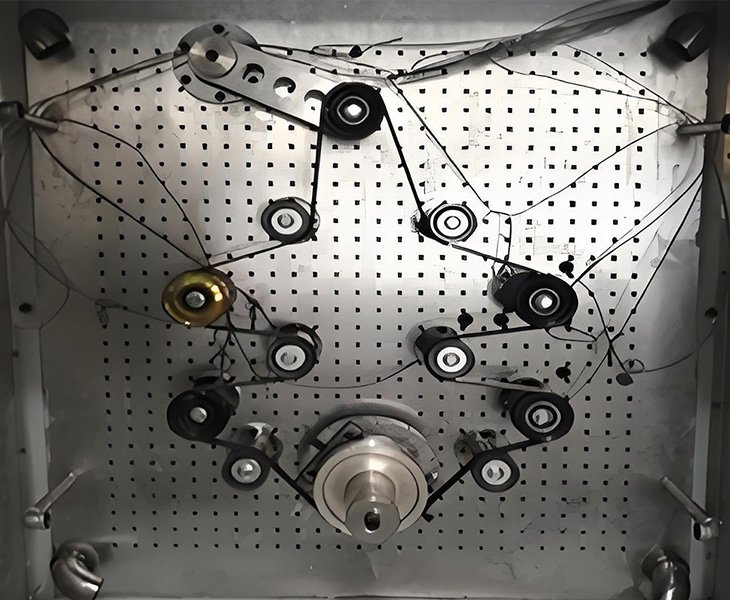

Up to now, DUHUI has more than 1,200 types of tensioner pulleys. Our tensioners are currently mainly mechanical tensioners and hydraulic tensioners, which can be adapted to most car models on the aftermarket, such as Honda, Toyota, Ford, Volkswagen, BMW, etc. Our tensioners perfectly meet the original equipment manufacturer (OE) standards for automotive engines. You can search for the same replacement parts in our product library by OE number.

DUHUI’s unique torsion spring and sealed bearing design can effectively reduce failures and increase the life of the tensioner pulley. Contact us to get a quote for a suitable tensioner pulley.

Tensioner And Auxiliary Pulley

Based on their function and role in the timing drive system, they are mainly divided into tensioner pulleys, idler pulleys, and guide pulleys.

High-Quality DUHUI Tensioner Pulley

The tensioner pulley is used to maintain the tension on the timing belt. If the tensioner pulley is of poor quality, it will affect engine efficiency or even damage the engine, causing a car accident. Therefore, the quality of the tensioner is very important. The entire manufacturing process of DUHUI tensioner is strictly in accordance with the national quality standard GB/T 13405-2020. Our tensioners are carefully tested by our professional QC team to ensure specifications and tolerances, and undergo individual quality testing. Only tensioners that meet these requirements are packaged.

Production Specification Control of DUHUI Tensioner Pulley

Strict standard requirements create high-quality DUHUI tensioner pulleys.

We have strict standard requirements for tensioners in the production process. For example, the radial clearance of the tensioner bearing must be controlled within 0.02-0.05mm, the diameter tolerance of the tensioner shaft hole must be controlled within H7 level (±0.018mm), and the tensioner body must be made of alloy steel with a hardness of HRC 50-60.

Targeted Quality Testing of DUHUI Tensioner Pulley

All DUHUI tensioner pulleys will be subject to strict quality testing. In addition to basic specifications testing such as the tensioner’s dimensional tolerances, we will do targeted quality testing, such as durability testing, salt spray testing, high and low temperature testing, etc.

We do salt spray tests on tensioner pulleys according to GB/T 10125-2012 standard, requiring 72 hours of continuous operation without rust. The durability test of our tensioner requires continuous operation for 120 hours at a speed of 4000r/min and a load of 500N. The high and low temperature tests of our tensioners require that they can operate normally between -40°C and 150°C, with no signs of aging.

A typical tensioner pulley consists of the following components: tensioner housing, tightening pulley bearing, tensioner spring, and tensioner piston. The tensioner pulley bearing is the most important, not only adjusting tension but also providing support.

The functions of the tensioner and auxiliary pulley are different, so their structures and designs are very different. I will tell you the differences between their functions.

The tensioner pulley can automatically adjust the belt tension according to the tightness of the belt, prevent the belt from loosening or falling off, and provide support.

The function of the auxiliary pulley is to assist the transmission.

The guide pulley is used to guide the belt, keeping it on track and preventing it from derailing. It also provides some support.

The idler pulley’s function is to assist in changing the direction of transmission.