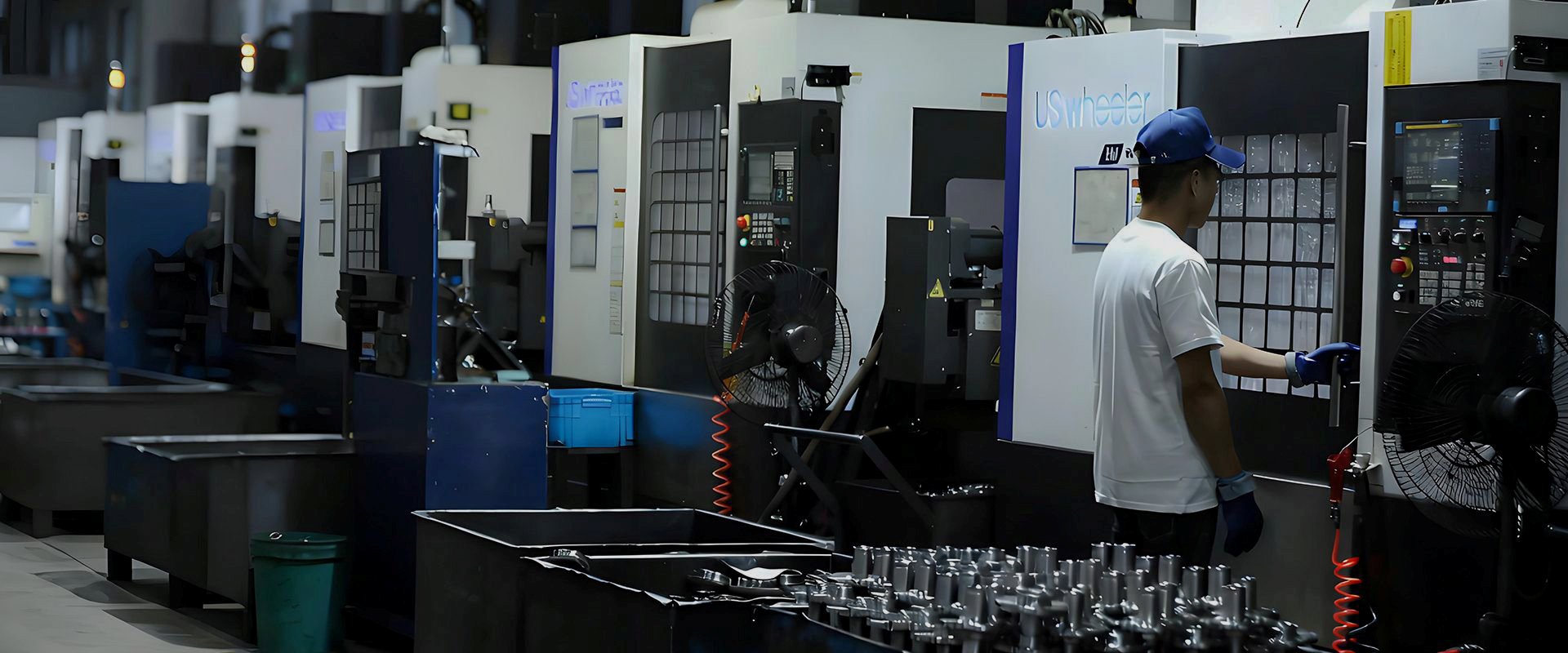

Our Own Bearing Factory and Partner Factories

Our own bearing factory is located in Zhejiang, China, and primarily manufactures wheel bearings and wheel hub assemblies, among other automotive chassis bearings. The factory covers an area of over 10,000 square meters, equipped with 39 CNC machine tools and 4 fully automated production lines, capable of producing 100,000 sets of bearings/units per month.

In addition, we have deeply integrated partner factories that can assist us with emergency production capacity and manufacture other bearings, such as tensioner pulleys.

Automated CNC Machine Tools and Production Lines

Although the structure of bearings may seem simple, the complete production process involves over 70 steps. By adopting advanced technology and purchasing state-of-the-art equipment, most of the bearing manufacturing processes in our factory have now been fully automated.

The following are some of our processing equipment:

- Sigma CNC precision turning machine

- Bearing grinding machines (outer ring/inner ring/race/flange)

- Bearing quenching machines

- Bearing Automatic Assembly Line

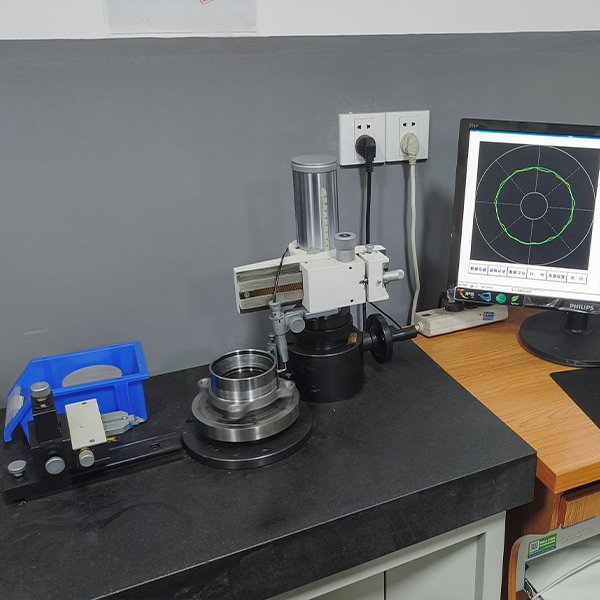

QC: The “Three No” Principle

Throughout the entire production process, we strictly adhere to the “Three No’s Principle,” controlling every step: “do not produce substandard products, do not accept substandard products, and do not release substandard products.”

From the selection of bearing materials to the manufacture and assembly of bearings, we have established strict inspection items and standards.

Our bearing testing procedures include, but are not limited to: fatigue life testing, roundness, profile, surface roughness, inner and outer diameters, microstructure analysis, clearance, and hardness.

Some Specialized Testing Instruments

DUHUI has built a professional testing laboratory, purchased professional testing equipment, and assembled a professional testing team. We have a 5-person testing team dedicated to the laboratory.

Fully automatic measurement of wheel hub bearing clearance

Fully automatic measurement of wheel hub bearing ABS signal

Testing the internal metallographic structure of the bearing

Certification

Below are some of our factory certificates, material certificates, and finished product inspection certificates.

ISO9001 Certification of DUHUI Bearing Manufacturer

ISO9001 Certification of DUHUI Bearing ManufacturerISO9001 is a quality management system certification, indicating that DUHUI has the ability to meet modern production standards and that we can provide bearings with guaranteed quality.

SGS Certification of DUHUI Bearing Manufacturer

SGS Certification of DUHUI Bearing ManufacturerDUHUI has passed the SGS factory audit, which shows that DUHUI meets international production requirements and the quality of the bearings we produce is guaranteed.

CNAS Laboratory Certification of DUHUI Bearing Manufacturer

CNAS Laboratory Certification of DUHUI Bearing ManufacturerCNAS laboratory accreditation demonstrates that DUHUI’s testing laboratory meets standards and that its test results are valid.

CNAS General Durability TEST of DUHUI Wheel Hub and Bearing Assembly

CNAS General Durability TEST of DUHUI Wheel Hub and Bearing AssemblyCNAS general durability test certification shows that the wheel hub bearings produced by DUHUI perfectly meet and exceed the OE standard.

STQ Matrial TEST of DUHUI Wheel Hub and Bearing Assembly

STQ Matrial TEST of DUHUI Wheel Hub and Bearing AssemblySTQ material testing is conducted on bearing steel raw materials, demonstrating that DUHUI selects high-quality bearing steel as its raw material.