Your Professional Cylindrical Roller Bearing Manufacturer

Cylindrical roller bearings have a unique cylindrical rolling element design. The cylindrical rolling element has a large contact surface with the raceway and has very good load-bearing capacity and stability. It can also effectively disperse the load on the car during driving, avoid excessive local pressure, and extend the life of the bearing. This design, used in automotive wheel bearings, can effectively withstand heavy loads while maintaining low friction and high stability.

Founded in 2003, DUHUI is a professional automotive bearing supplier in China with TS16949 and ISO9001 certifications. We have extensive experience in the R&D and manufacturing of cylindrical roller bearings. To meet the special requirements of automotive wheel bearings, we have improved materials, processes and designs. Our factory has 4 fully automatic production lines, which can steadily supply 100,000 sets of high-quality cylindrical roller bearings per month. We can provide over 2,400 models of cylindrical roller bearings, which can cover most car models in the aftermarket, such as Toyota, Honda, Volkswagen, etc. DUHUI bearings are well-known in Europe, North and South America.

DUHUI adheres to strict production and quality inspection standards to ensure that every cylindrical roller bearing meets or exceeds original equipment manufacturer (OE) quality standards. Our bearing precision can reach above P6. We select high-quality GCR15 bearing steel as raw material and use tempering, quenching, normalizing and other heat treatment processes during the processing to ensure that the bearings can improve the surface hardness while maintaining internal toughness. Our bearings have excellent impact and wear resistance, and can effectively withstand the load and wear of long-term high-speed driving.

DUHUI has more than 20 years of professional experience in cylindrical roller bearings. Our bearings cover various types including single row and double row. We also have 15 years of experience in foreign trade and are very familiar with the customs clearance and tax declaration of bearing imports and exports, as well as the local policies of the destination country. We believe we can be of great help to you. Contact us and we will prepare a local hot-selling bearing catalog for you.

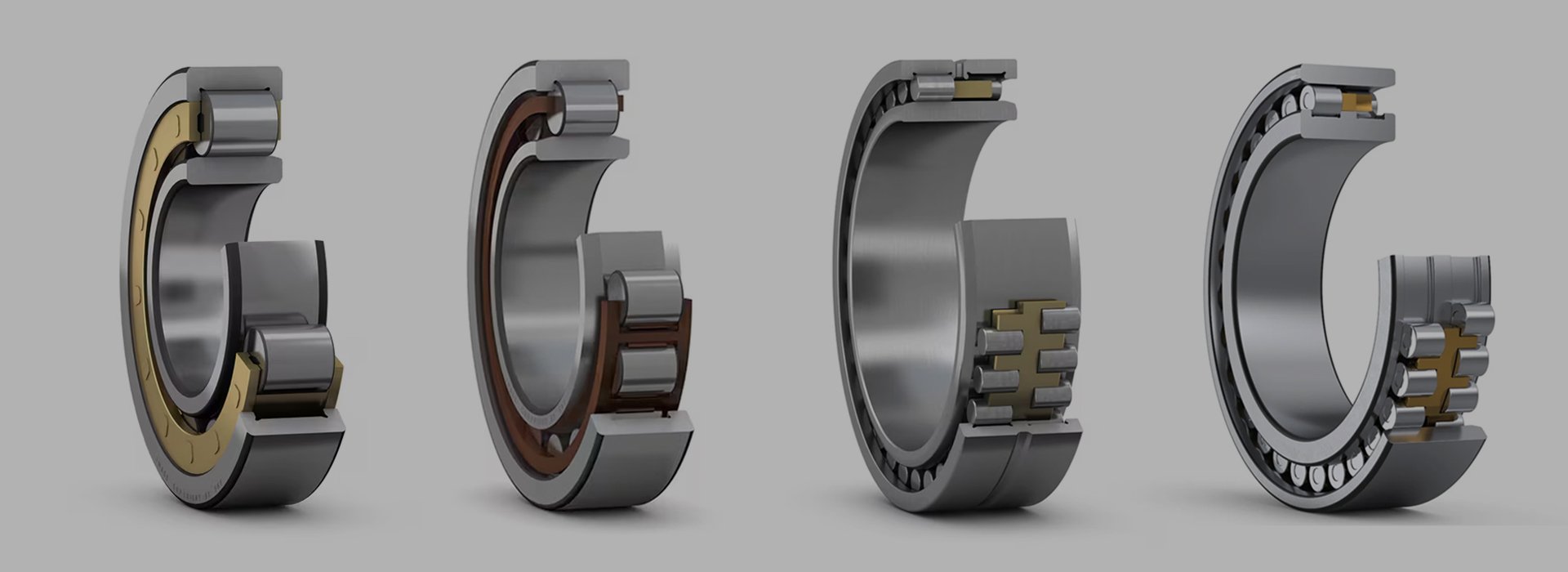

Cylindrical Roller Bearings By Rows

Cylindrical roller bearings are classified into single-row and double-row cylindrical roller bearings based on the number of rows of cylindrical rollers.

Single Row Cylindrical Roller Bearing

Single Row Cylindrical Roller BearingThey offer lower cost and are more suitable for lightweight and compact designs.

Double Row Cylindrical Roller Bearing

Double Row Cylindrical Roller BearingThey also offer higher load capacity and greater stability.

Heat Treatment of DUHUI Cylindrical Roller Bearings

The heat treatment process is a very important part of bearing processing. Tempering can optimize the internal structure of the bearing. Quenching can improve surface hardness, wear resistance, etc. Normalizing can improve internal toughness, fatigue, etc. DUHUI’s technical experts have specifically improved the heat treatment process to achieve a balance between surface hardness and internal toughness, thereby extending bearing life. Our tempering process standard requires heating to a high temperature of 600°C followed by a constant temperature of 200°C for four hours.

DUHUI Cylindrical Roller Bearing Production Line

DUHUI has introduced advanced bearing manufacturing technology and fully automatic CNC machine tools. Our production line uses fully automatic CNC machine tools + manual assistance for manufacturing. These fully automatic CNC machine tools ensure that our bearings are manufactured with micron-level precision. The roughness of our bearing raceways can reach 0.1 micron standard after finishing and super finishing. Manual assistance is mainly for machine debugging and tolerance testing to ensure a stable and high-quality supply of bearings.

Quality Inspection of DUHUI Cylindrical Roller Bearings

In addition to QC during the production process, DUHUI has a dedicated quality inspection team responsible for the overall testing of the cylindrical roller bearings. During the manufacturing process, we will conduct basic tolerance, clearance and other tests. We also have a dedicated testing room equipped with length gauges, profilometers, hardness testers, roundness testers, roughness testers, and other equipment. We also have CNAS material inspection and quality inspection reports. If you need other relevant certifications, we can also provide.

DUHUI bearings are typically packaged in white boxes or DUHUI-branded color boxes. We can also customize branded color boxes for you.

We are capable of customizing non-standard bearings based on drawings or samples.

Usually, our MOQ is 50 pieces.

We have two after-sales teams, both domestically and internationally, offering 24/7 service. If any quality issues arise, we offer discounts or refunds.