Your Professional Clutch Release Bearing Manufacturer

DUHUI clutch release bearing manufacturer was founded in 2003 and was ISO9001 and 16949 certified. We are a professional manufacturer with international automotive industry certifications. Our clutch release bearings are manufactured and tested in strict accordance with the Chinese national standard JB/T5312-2001. DUHUI can provide material inspection certificates and finished product inspection certificates related to clutch release bearings. And we can handle access certificates for corresponding countries, such as the EU CE certification and the US DOT certification.

DUHUI can provide you with comprehensive and economical clutch release bearing solutions. Now we have more than 1,200 types of clutch release bearings, which can cover the major Japanese, Korean, European, and American car brands, such as Honda, Toyota, Hyundai, Ford, Volkswagen, etc. All DUHUI clutch release bearings (DH12 series) can be replaced with the spare parts from original equipment manufacturer (OEM), and are guaranteed to meet original OE standards. Our clutch release bearings are trusted in the automotive aftermarket. Welcome to contact us for a quotation.

Automotive Release Bearing By Driving Method

Based on its driving method, automotive clutch release bearings are mainly divided into mechanical clutch release bearings and hydraulic clutch release bearings.

Clutch Release Bearing

Clutch Release BearingMechanical clutch release bearings rely on mechanical cables or levers for transmission, resulting in slightly lower efficiency, but they are simpler in structure and lower in cost.

Hydraulic Release Bearing

Hydraulic Release BearingHydraulic clutch release bearings rely on hydraulic oil for transmission, offering higher efficiency, greater accuracy, and easier operation.

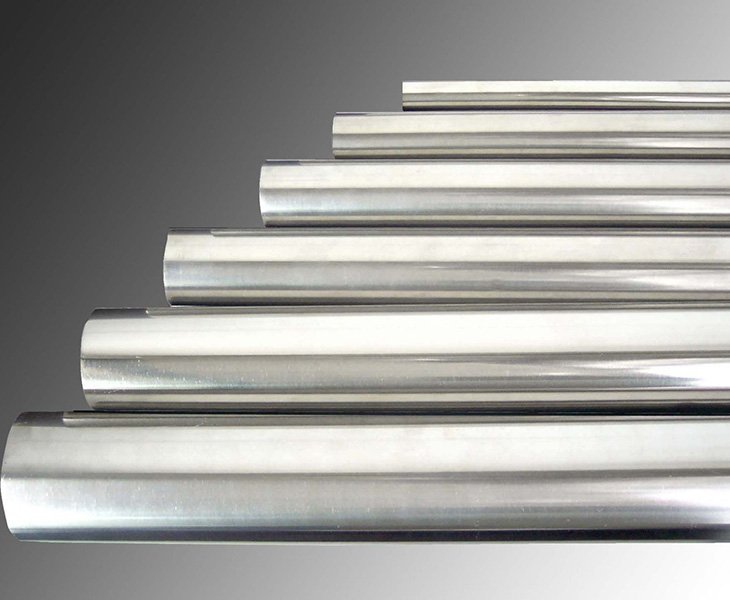

Materials and processes of DUHUI clutch release bearings

DUHUI uses high-quality GCR15 bearing steel to manufacture the inner and outer rings of the clutch release bearings, and performs quenching and tempering to ensure a surface hardness of over 58HRC. Finally, the surface is sandblasted and coated with anti-rust oil to ensure wear resistance and corrosion resistance. DUHUI uses high-quality white Japanese lubricating grease, which is sealed and lubricated for life, reducing friction and loss and extending bearing life.

Manufacturing standards of DUHUI clutch release bearing

DUHUI manufactures clutch release bearings in strict accordance with the Chinese national standard JB/T5312-2001. Our clutch release bearings require axial clearance ≤ 0.60mm and inner race wear ≤ 0.30mm. Our carburizing heat treatment must comply with JB/T 8881-2001 standard, which requires the surface carbon concentration to reach 0.8%-1.0% and the effective hardened layer depth to be ≥0.5mm to ensure impact resistance.

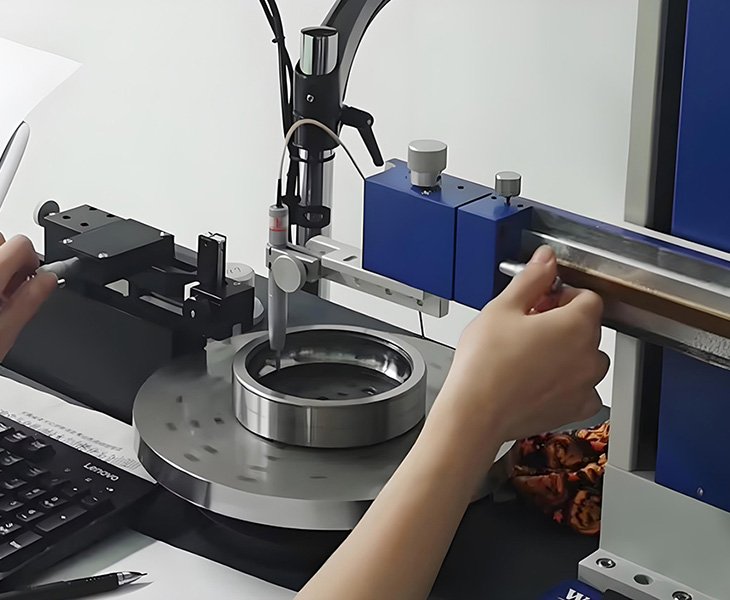

Quality testing of DUHUI clutch release bearing

DUHUI will do multiple rigorous tests on the materials and finished products of clutch release bearings. The GCR15 bearing steel used for the inner and outer rings is required to pass the JB/T 7361-1994 hardness test, with a hardness deviation of ≤±1.5HRC. For finished clutch release bearings, we mainly conduct high and low temperature tests, requiring normal use at -40℃ to 150℃; salt spray test, requiring no rust within 72 hours; fatigue test, requiring 300,000 times of normal use, no oil leakage, no damage, etc.

The main advantages of DUHUI clutch release bearing are low failure rate, relatively low price, and low maintenance costs. And it is more stable and durable in harsh environments.

High-quality DUHUI clutch release bearings can achieve a service life of 3 years/100,000 kilometers under normal use.

If you find any of these two symptoms, your clutch release bearing may be bad: There’s a noise when you press the clutch pedal, or the clutch pedal is difficult to press. Visit a repair shop for an inspection as soon as possible.