Professional Angular Contact Ball Bearing Manufacturer

The unique inner and outer ring raceway design of angular contact ball bearing enables it to bear both radial and axial loads. And its axial load-bearing capacity increases with the increase of contact angle. The smaller the contact angle, the more suitable it is for high-speed movement. This design is very suitable for the automotive industry, and different angular contact ball bearings can be adapted to different car models.

DUHUI is a leading automotive bearing manufacturer in China. Our products include a variety of single and double row angular contact ball bearings. We have been engaged in the bearing manufacturing industry for 20 years, and have rich experience in R&D and manufacturing. The quality of our bearings is trustworthy. We can provide you with competitive bearing quality and price.

DUHUI angular contact ball bearings are made of high-quality GCR15 bearing steel (equivalent to US 52100 steel), which is of excellent quality and can ensure the life of the bearings. Our bearing balls are guaranteed to meet G10 standards and can be customized to G5. Our bearing raceways are precision finishing and superfinishing to effectively reduce noise and friction. We use advanced lubrication and sealing technology, and import high-quality grease from Japan to effectively ensure the performance of the bearings. And our angular contact ball bearings are subject to 100% quality inspection, ensuring reliable quality.

We not only provide high-quality angular contact ball bearings, but also provide high-quality services. DUHUI has been exporting bearings for 15 years. We have rich experience in bearing customs clearance and can assist you in importing bearings. Our business team is always at your service.

DUHUI offers a variety of single-row and double-row angular contact ball bearing solutions. Our bearing catalog has more than 2,000 types of angular contact ball bearings and is constantly being improved. Contact us to request a detailed bearing catalog.

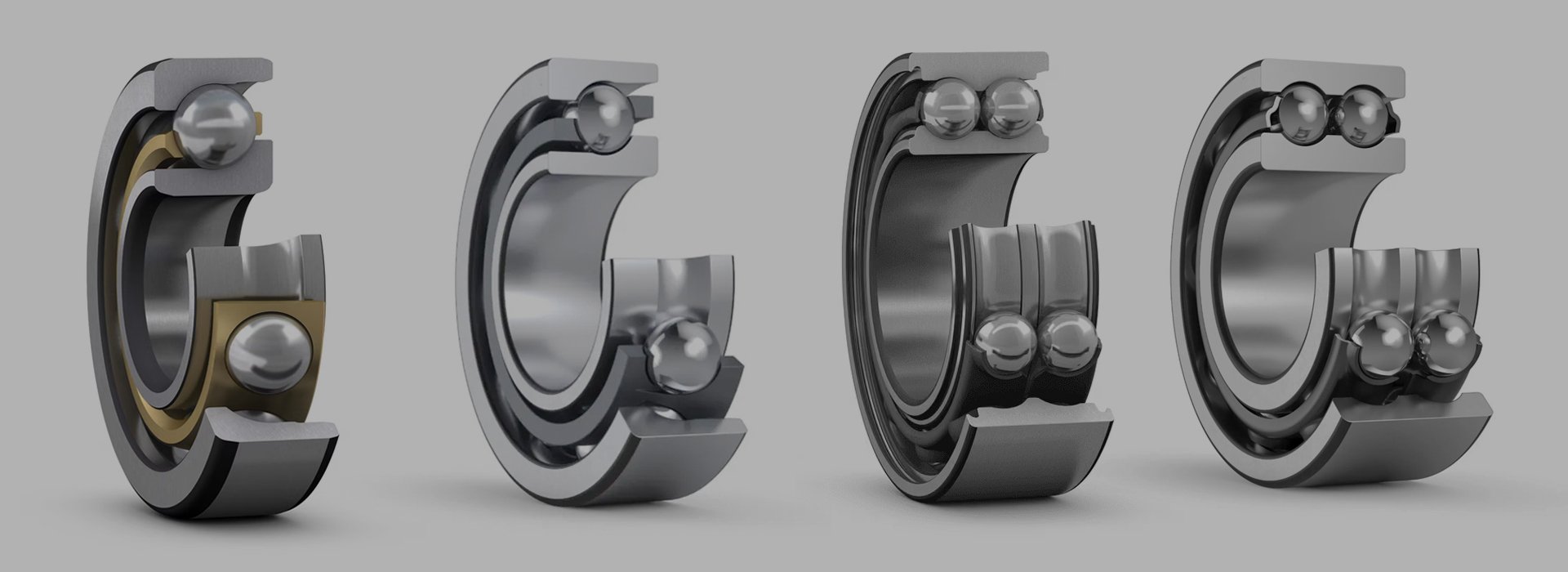

Angular Contact Ball Bearings By Rows

There are two main types of angular contact ball bearings: single-row and double-row angular contact ball bearings.

Single-Row Angular Contact Ball Bearing

Single-Row Angular Contact Ball BearingSingle-row angular contact ball bearings can be freely combined, offering greater flexibility.

Double-Row Angular Contact Ball Bearing

Double-Row Angular Contact Ball BearingDouble-row angular contact ball bearings are factory-matched, providing stronger stability.

DUHUI Single Row Angular Contact Ball Bearing

Due to the contact angle, single-row angular contact ball bearings will be subject to axial force when bearing radial loads, and usually need to be used in pairs or more. DUHUI can design a complete installation solution for you to achieve optimal performance. We can customize back-to-back (DB), face-to-face (DF), and tandem (DT) installation to meet your specific needs.

DUHUI Double Row Angular Contact Ball Bearing

Double row angular contact ball bearing has two rows of balls, which is equivalent to a combination of two single row ball bearings, but saves more space. Due to the double-row design, double-row angular contact ball bearings can both bear radial loads and axial loads, and have a stronger load capacity. Combined with DUHUI high-precision balls and superfinishing raceways, the load can be further dispersed to improve the bearing capacity. And it can also effectively reduce vibration and noise and extend bearing life.

Customized Contact Angles and Cages

DUHUI can customize angular contact bearings with contact angles of 15°, 25°, 30°, and 40° depending on your needs. Bearing cages can also be customized with various materials, including stamped steel (mild steel), copper alloy, bakelite, and nylon 66.

DUHUI uses high-quality, high-purity GCR15 bearing steel (1.0% carbon content, 1.5% chromium content). Normalizing eliminates stress, making the internal structure more stable and effectively improving the material’s fatigue life.

During the machining process, DUHUI angular contact ball bearings undergo three finishing steps and two superfinishing processes. Each step is inspected for tolerance using a specialized bearing tester. After superfinishing, the surface roughness is controlled to approximately 0.1μm.

DUHUI requires our angular contact ball bearings to operate at 1.5 times the rated speed for 240 hours without significant temperature fluctuations and stable vibration values.

DUHUI requires our angular contact ball bearings to withstand 200% standard load for 72 hours without plastic deformation.

DUHUI requires that our angular contact ball bearings operate normally at temperatures between -40°C and 120°C, and must pass a 72-hour salt spray test with no visible signs of corrosion.

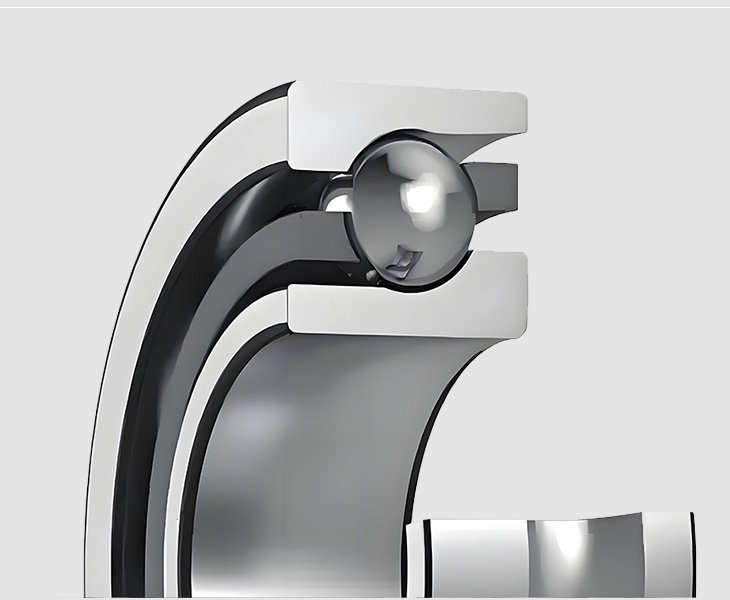

The ball and outer ring of an angular contact ball bearing have a contact angle. By adjusting the contact angle, the bearing’s load capacity can be adjusted.

Look at the thickness of the bearing’s outer ring on both sides. Deep groove ball bearings have equal thickness on both sides of their outer ring. Because angular contact ball bearings have a contact angle, the thickness on both sides is not equal.

Double-row angular contact ball bearings have limited contact angle options.

Single-row angular contact ball bearings have no contact angle restrictions and can be customized for optimal performance.

In addition, the clearance and accuracy of double-row angular contact ball bearings are factory-controlled, effectively improving vibration, noise, and rotational accuracy.