Your Professional Tapered Roller Bearing Manufacturer

Tapered roller bearings are similar to angular contact ball bearings, and also have a contact angle. However, tapered roller bearings use line contact, which results in a larger contact area and a stronger load capacity. And tapered roller bearings can also bear axial and radial loads at the same time. Therefore, tapered roller bearings are very suitable for automobile wheel bearings.

DUHUI is a leading automotive bearing manufacturer in China, with over 20 years of professional R&D and manufacturing experience on tapered roller bearings. Our technical experts have specially improved the design of tapered roller bearings to make them more suitable for automotive wheel bearings. Our tapered roller bearings have a 30% higher load capacity and 20% lower vibration and noise than typical bearings on the market. In the automotive bearing aftermarket, DUHUI means good quality and long life.

We use high-quality GCR15 bearing steel as raw material, which complies with the Chinese GB/T 18254 standard. We require that each batch of bearing steel must undergo CNAS material testing to ensure that its carbon, chromium and other contents and internal structure meet the standards. In addition to strictly selecting raw materials, we also use heat treatment during the processing to improve the performance of bearings. For example, after forging, we use four hours of high-temperature normalizing to improve toughness of bearing.

DUHUI can provide over 2,400 types of tapered roller bearings, including single row and double row. Our bearing library includes most tapered roller bearings available on the aftermarket. All bearing parameters meet the original OE standards and can be used in the aftermarket. We can also customize bearings for you. Contact us to obtain the DUHUI tapered roller bearing catalog.

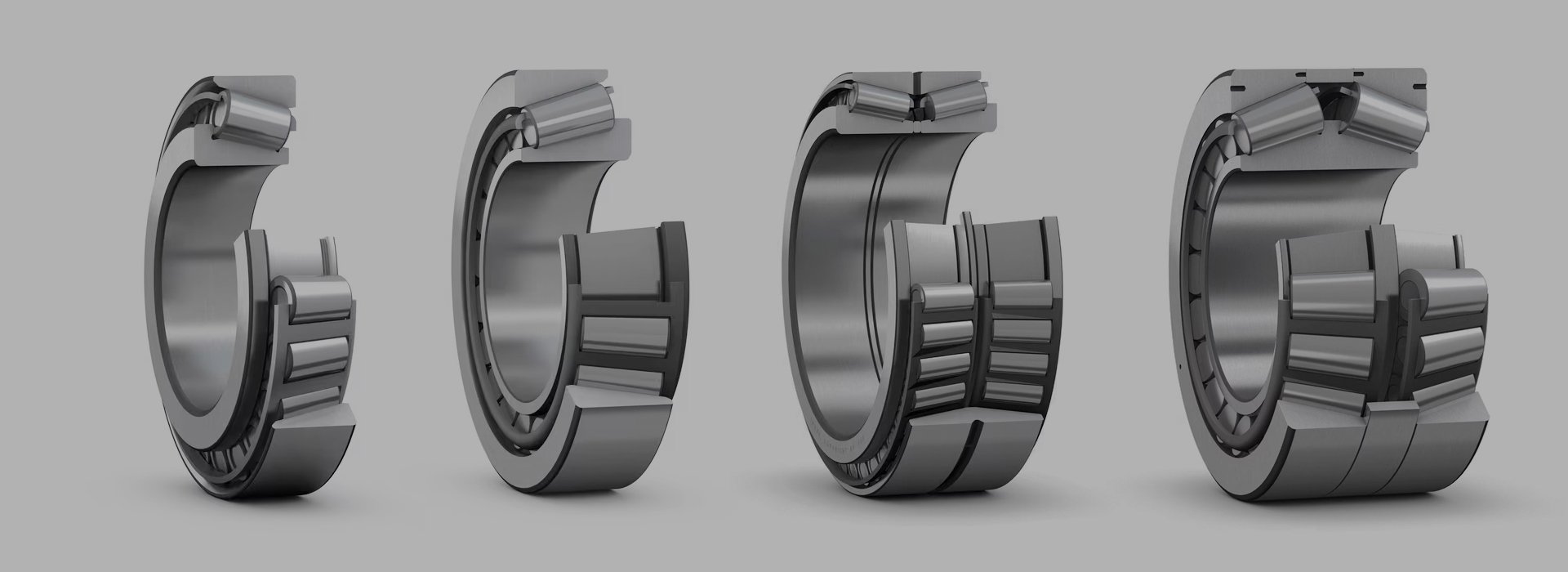

Tapered Roller Bearings By Rows

Tapered roller bearings are mainly classified into single-row and double-row tapered roller bearings based on the number of roller rows. They are further subdivided according to their contact angle and inner and outer ring structure.

Small angle series: Contact angle between 10° and 18°, accommodating both radial and axial loads.

Large angle series: Larger contact angle (approximately 25°-29°), stronger axial load capacity, but slightly weaker radial load capacity.

TDO type (double outer ring, single inner ring): The TDO (Transparent Domino) structure consists of two single-row inner rings and one integral outer ring. The rigidity is better.

TDI type (double inner ring, single outer ring): The TDI (Transparent Diode) structure consists of two single-row outer rings and one integral inner ring. The structure is more compact.

Strict Production Standards of DUHUI Tapered Roller Bearings

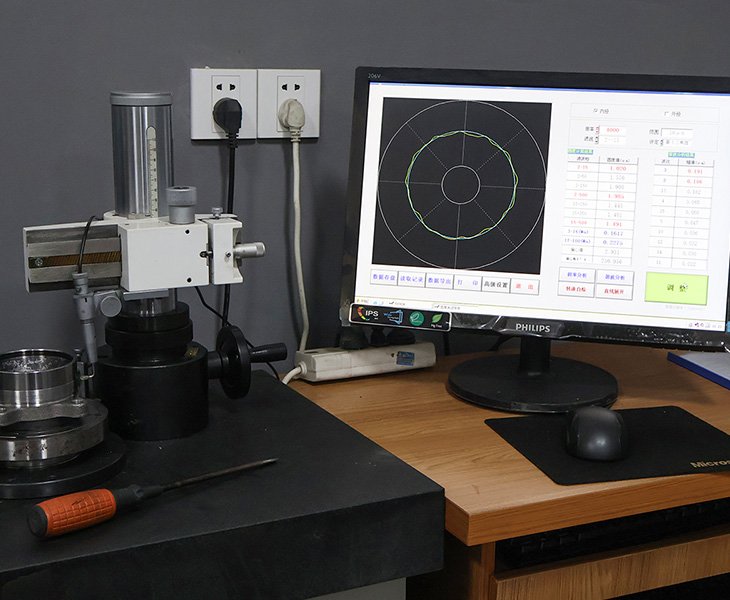

If the bearing precision does not meet the standards, it will affect the life of the bearing and may even cause the bearing to be unusable. To ensure that the bearings meet the precision standards, DUHUI has established very strict production standards. For example, to achieve the required 0.1 micron surface roughness of the bearing raceway, we perform turning, finishing, and superfinishing, carefully controlling the allowance and accuracy at each step. Each step is equipped with specialized tolerance testing equipment.

Strict Testing Standards of DUHUI Tapered Roller Bearings

Before the tapered roller bearings are shipped, DUHUI will conduct multiple quality tests. Our tests strictly meet with national testing standards. The strength of all tests meets or even exceeds national standards. For example, for high and low temperature environmental testing, we require cyclic testing between -40°C and 150°C for 480 hours. And finally we ensure that the bearings exhibit no dimensional deformation and that their lubrication performance is normal.

Improved Packaging Design of DUHUI Tapered Roller Bearings

During long-distance sea transportation, bearings are easily damaged. Sometimes it is not just the outer packaging that is damaged, it can even affect the bearings. DUHUI has improved our entire product packaging based on actual conditions. After completing basic testing, we apply anti-rust oil to the bearings and then wrap them in PP plastic bags. We then add bearing protection sleeves and honeycomb pads for impact protection and pack them into a box. Finally, we pack them into cartons and pallets according to the box size.

Yes, we can provide CNAS material and performance test certificates. If you require other certifications, we can also provide them.

We can provide DUHUI branded tapered roller bearings, ensuring that all bearings meet original equipment manufacturer (OE) standards. We also support OEM and ODM services.

For tapered roller bearings, our minimum order quantity is 50 pieces per specification.