Your Reliable Wheel Bearing Supplier

DUHUI was founded in 2003, and has more than 20 years of experience in wheel bearing manufacturing. Our wheel bearings (DWB series) can fully comply with the original OE standards. Our DWB codes are compatible with the codes of bearing manufacturers such as SKF, NSK, FAG, etc. In our bearing library, you can accurately find replacement bearings by simply searching the OE code. We can currently produce more than 4000 models of wheel bearings, which are widely used in the automotive industry, including family cars, commercial cars, pickup, and trucks.

From bearing material selection to production and assembly, DUHUI strictly adheres to quality standards, without cutting corners. We use high-quality GCR15 (AISI 52100) bearing steel as the main material. GCR15 bearing steel has the advantages of high hardness, good wear resistance, and high fatigue strength. The bearing steel produced by GCR15 is of better quality and longer life. During the processing, we use processes such as case carburization and polished raceways to improve the durability of the bearings. The matching lubricants we use are also high-quality Japanese lubricants.

Our wheel bearing factory has ISO 9001 and 16949 certifications, and has professional capabilities in producing and processing wheel bearings, which is capable of accepting custom orders for wheel bearings. The bearing steel we use will also have the STQ material test report, and the final wheel bearing will also have the CNAS test report. Please feel free to contact us.

Wheel Bearings By Car Model

The wheel bearings are categorized according to the best-selling car models and bearing lines. And our sales staff conduct regular market research and analysis, and we will create a catalog of the best-selling bearings for each region for you.

Best-selling wheel bearings for Honda Civic Accord, and other models

Best-selling wheel bearings for Toyota RAV4 Corolla, and other models

Best-selling wheel bearings for Nissan Sentra Altima, and other models

Best-selling wheel bearings for Volkswagen Jetta Atlas, and other models

Best-selling wheel bearings for Hyundai Elantra Kona, and other models

Best-selling wheel bearings for Benz C-Class C300 , and other models

Best-selling wheel bearings for BMW 3-Series X-Series, and other models

Best-selling wheel bearings for Audi A-Series A3 A6, and other models

Best-selling wheel bearings for Mazda 3 5 CX3 CX5, and other models

Best-selling wheel bearings for Lexus RX350 GX550, and other models

Best-selling wheel bearings for Kia Sportage Sorento, and other models

Best-selling wheel bearings for Chevrolet Trailblazer Equinox, and other models

Best-selling wheel bearings for Jeep Wrangler Cherokee, and other models

Best-selling wheel bearings for Ford Ranger Escape, and other models

Best-selling wheel bearings for Volvo XC-Series XC40 XC60, and other models

Wheel Bearings By Bearing Type

The main classification is based on the rolling elements of the bearing. Bearings are classified into single-row and double-row bearings based on the number of rows of rolling elements. Based on the type of rolling elements, they are classified into ball bearings and roller bearings, and more specifically, deep groove ball bearings, angular contact ball bearings, tapered roller bearings, cylindrical roller bearings, etc.

Low friction, suitable for low-load, high-speed operation

Complex structure, high load capacity, and strong stability

Withstands unidirectional axial loads. Requires pairing for use. More flexible.

Withstands bidirectional axial and radial loads. Factory paired. More stable.

Customizable bearing contact angle, adjustable bearing clearance

Integrated from two single rows, factory-preset clearance, stronger load capacity

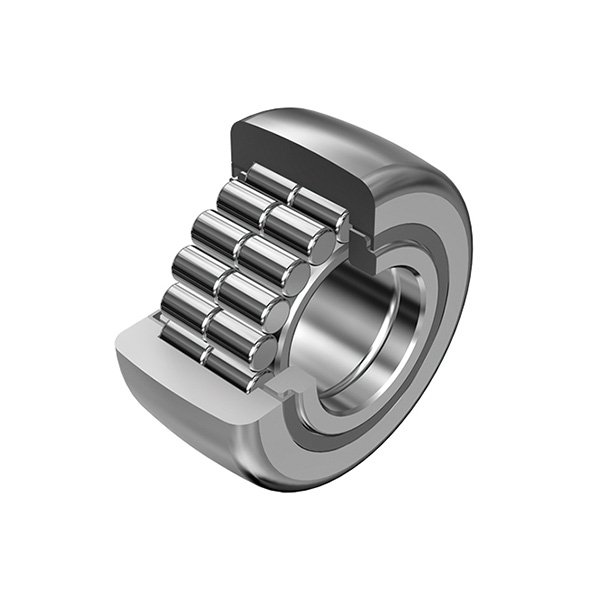

Line contact, large contact surface, strong load capacity. Low friction, high-speed rotation

An upgrade from the single-row design, with even stronger load capacity.

Its compact structure makes it suitable for small spaces. Low friction, suitable for high speeds. It also has a strong load capacity.

We can customize various non-standard bearings according to drawings and samples.

The Materials of DUHUI Wheel Bearings

A wheel bearing consists of a rolling element, an inner ring, an outer ring, and a cage.

All components of DUHUI bearings are made of high-quality materials and are quality tested.

For the rolling elements and inner ring, we chose GCR15 carbon chromium steel for its high strength and good wear resistance.

For the outer ring, we chose 65MN manganese steel for its good toughness and impact resistance.

Cages come in two types: metallic and non-metallic. Generally, non-metallic materials are more common. We use heat-resistant nylon PA66 with glass fiber, which is lighter and offers excellent heat and wear resistance.

Strict Process Standards of DUHUI Wheel Bearings

A high-quality wheel bearing requires not only high-quality materials but also precise production processes and standards.

DUHUI’s seven bearing experts have improved bearing production processes and established strict production standards, reducing the customer complaint rate for bearings to 0.5%.

To reduce costs, some manufacturers skip tempering after forging and proceed directly to rough turning, or fail to meet tempering temperature and time standards. This may not cause any problems initially, but can significantly reduce the bearing’s lifespan.

We not only require tempering, but also adhere to strict standards. We first heat the bearing to 600°C, then cool it to 180-200°C, maintaining this temperature for 3-4 hours to allow the internal structure to stabilize.

Wear-resistant Rubber Seals of DUHUI Wheel Bearings

DUHUI wheel bearing seals are made of high-quality wear-resistant rubber, which can be divided into contact seals and non-contact seals, according to whether the seal is in direct contact with the moving parts.

DUHUI currently generally uses non-contact 2RZ seals, which have good waterproof and dustproof effects. And the seals do not directly contact the moving parts, so there is no friction effect, and the performance is better.

Imported White Lubrication of DUHUI Wheel Bearings

DUHUI wheel bearings use high-quality Japanese white Lubricating grease, which can better exert bearing performance and extend service life.

Our bearings are also tested at high and low temperatures before leaving the factory to ensure that the lubricating grease can work normally in different environments.

Our wheel bearings are typically packaged in unbranded white boxes or boxes with our own logo. We also fully support custom packaging with your brand upon request.

Our wheel bearing can be used for about 120,000 kilometers. If you often drive in complex conditions such as mountains or muddy ground, the life of the bearings will be shortened.

All DUHUI bearings undergo rigorous testing before shipment.

Our test includes:

- Performance tests such as roundness, profile, roughness, inner and outer diameters, and clearance;

- Environmental tests such as simulated mud;

- Life tests such as high and low temperature tests and fatigue strength tests.

Yes, we can not only produce various national standard bearings, but also customize non-standard bearings according to your drawings and samples.

Wheel bearings specifically refer to first-generation automotive wheel bearings. Wheel bearings have a relatively simple structure, mainly consisting of rolling elements, an inner ring, an outer ring, and a cage. The rolling elements typically use balls or tapered rollers.

The wheel bearing is a key component that connects the car wheel to the axle. Its outer ring is connected to the wheel, while its inner ring is connected to the axle. The wheel bearing has three main functions:

First, it supports load. The wheel bearing bears the weight of the entire vehicle body.

Second, it reduces friction. The wheel bearing reduces friction between the wheel components.

Third, it guides the wheel’s steering. The wheel is connected to the axle through the wheel bearing, and the wheel’s steering is guided by the wheel bearing.

The first generation wheel bearings had a relatively simple structure, so their classification was also relatively simple.

Based on the common rolling elements, they were categorized into ball bearings and tapered roller bearings.

Based on the single or double row, they were categorized into single-row bearings and double-row bearings.

This resulted in the four most common types:

- Single-row angular contact ball bearings

- Double-row angular contact ball bearings

- Single-row tapered roller bearings

- Double-row tapered roller bearings

In addition, some cylindrical roller bearings, needle roller bearings, and non-standard bearings may also be available.

If a wheel bearing is damaged, these four symptoms will tell you:

- Noise: A damaged wheel bearing can cause metal collisions, and you will hear a noticeable piercing noise.

- Abnormal vibration: A damaged wheel bearing can cause the bearing to operate sluggishly, and you may feel abnormal vibrations in the car body or stiff steering.

- Tire wear: A damaged wheel bearing can cause uneven drive force, leading to uneven tire wear.

- Wheel temperature: A damaged wheel bearing can generate significant frictional heat. If you touch the wheels with your hands, you can feel that they are noticeably hot.

Replacing first-generation wheel bearings is more complex than replacing wheel bearings. The wheel bearings are press-fit bearings, requiring specialized tools and specific procedures.

If you are not a professional in the auto repair industry, I suggest you go to a repair shop to replace it.

There are two costs involved: the cost of the bearing and labor.

Purchasing a high-quality bearing from DUHUI costs approximately $10-30. If you’re a professional, you can choose to replace it yourself.

If you go to a repair shop, the labor cost alone is $50-100. If you choose to purchase the bearing from a repair shop, you might need to add an additional $5-10 to the price of the bearing.

If you’re a professional auto mechanic with specialized tools like a jack and a pressure gauge, the replacement should take about 1.5 hours.

If you choose to go to a repair shop to replace the bearing, it will be much faster and only take about 30 minutes.